COMMERCIAL ELECTRICIANS

Decades of experience dealing with complex, time sensitive projects is what makes ATS so unique, and our commercial electricians amongst the best in Victoria.

Our team have worked with a number of large commercial establishments including Monash University; Holden; Hallmark and more to create custom solutions that suit their needs to their budget. At ATS, our electricians pride themselves on performance, and this is demonstrated by our long list of happy clientele and repeat business.

Below is a snapshot of a few projects led by our talented commercial electrician team. This is just a small sample of our award winning work. As ATS continues its march to further growth and success, our commercial electricians lead the way. Although we’re very proud of our past projects we understand that every job has its own challenges. To discuss your own requirements, please contact us on 1300 287 000. We would be more than happy to discuss your needs.

Commercial Electricians Project:

Willow Ware Australia - 3000 Amp Power Supply Installation & Conveyor System Upgrade

Willow initially asked the commercial electricians at ATS to offer recommendations and quotation for a proposed upgrade of their conveyor system. During these discussions, it was identified additional power supply would be required to facilitate any conveyor upgrade. An upgrade of the power supply would also require consultation with the Melbourne Airport Authority and the Supply Authority.

ATS submitted a design and construct proposal that outlined the requirements to facilitate the connection of the upgraded conveyor system and an additional 16 extruders. The project was completed ON TIME which was a great effort by the ATS team considering unavoidable external delays to the project. ATS received a Certificate of Commendation for this commercial project from NECA at their Awards of Excellence.

Commercial Electricians Project:

Melbourne Grammar School - LOTE Drama Centre

ATS were the electrical sub-contractor to Buxton Constructions as the winning tenderer for this project. The project involved the internal refurbishment of the upper level of four interconnecting heritage buildings to become a new LOTE (Language other than English) Centre and Drama teaching facility. The end result of the ATS work has been a remarkable transformation of a dysfunctional area into a vibrant teaching and resource space. The space has excellent lighting, power, data and audio fixtures and fittings that represent both the challenges and rewards that come from the School having heritage buildings. These buildings need sensitive restoration to maintain their historic links yet make them highly functional for today’s students.

The School is very pleased with works provided by ATS and the outcome of this project.

Commercial Electricians Project:

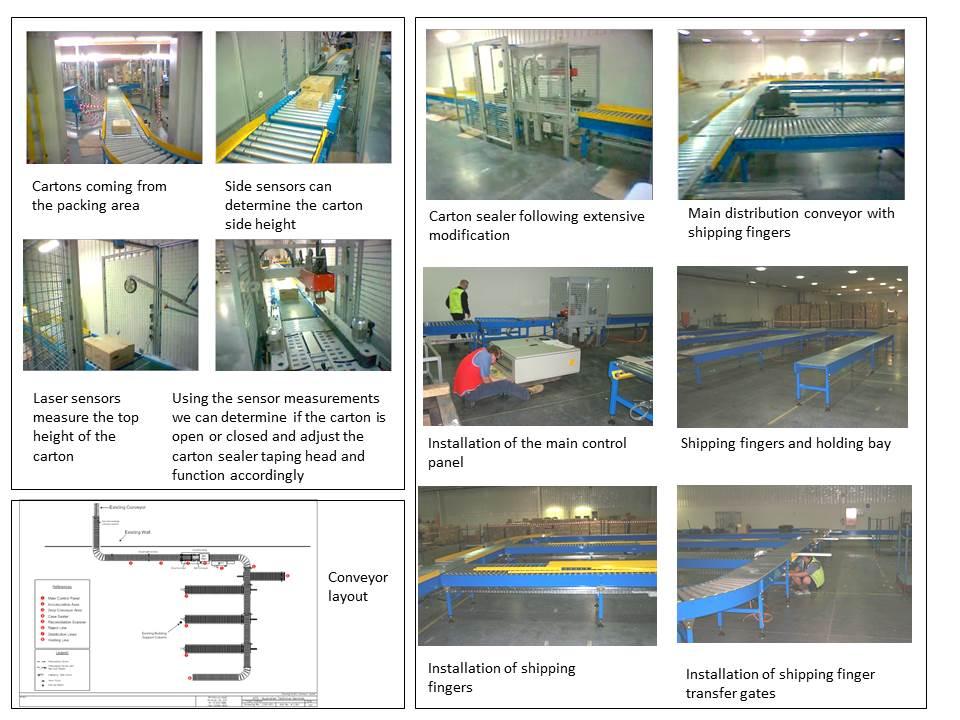

Hallmark Cards Carton Distribution Engineering Solution

ATS were first invited to Hallmark Cards to assist with the integration of their barcode reading equipment into a new carton conveying system. During the design briefing, ATS offered suggestions to alter the conveyor layout and modify the carton sealer. This then enabled continuous carton flow by detecting carton size, or carton open/closed status.

After further design meetings, ATS was contracted to implement a turnkey conveying solution and additionally assisted the Hallmark Cards IT team to integrate their order/packing system with the distribution conveyor system.

The ATS solution provided complete flexibility of operation while satisfying all elements of the design brief. By interfacing with the existing conveyors control system, ATS were able to control the pre accumulation area delivery of cartons to the new conveyor area.

Unfortunately, when the pre-ordered tape machine was delivered, it was discovered it was not manufactured as per the specification and therefore could not automatically close the cartons without operator assistance. A replacement would be 12 weeks away, which did not fit the tight time line available.

To solve this issue ATS designed and implemented a series of modifications to provide this functionality over the full range of carton sizes. This included detecting the carton size on the conveyor, and whether it was open or closed. This allowed any combinaton of carton size to be delivered down the conveyor at any time. Additionly, the modifications allowed sealed cartons to be passed through without re-taping, thus saving time and tape!